The story of diethyl malate traces back to a time when organic acids began grabbing attention in labs across Europe. Chemists set out to tweak the building blocks of malic acid, a compound that gives apples their snap and tanginess. By reacting malic acid with ethanol under acidic conditions, early experimenters noticed something different—a liquid that left behind the thought of fruit and became something entirely new. Through the 19th and 20th centuries, updates in distillation and purification made this diethyl ester accessible to anyone studying organic synthesis. From industrial labs trying to beef up chemical processes to university scholars investigating reaction mechanisms, the compound held its ground across many decades.

Walk into a chemical stockroom, you'll see diethyl malate listed among its esters: a colorless, oily liquid, not one that usually gets the spotlight but finds plenty of use around the edges. Technicians choose it when they need a mild flavorant, a coupling agent, or an intermediate to make bigger molecules. With a faint, agreeable odor and a taste that’s hard to pin down, diethyl malate earned followers in specialties from fragrances to solvent blends. For many, it’s less about the product itself and more about where it fits in bigger workflows—whether it's standing in as a reactant, dissolving stubborn solids, or giving a formulation some flexibility.

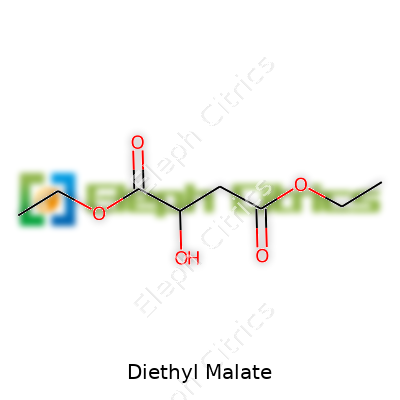

Think of diethyl malate the next time you pour olive oil—slippery, clear, and a bit heavier than water. This ester weights in with a molecular mass of 174.19 g/mol. Its boiling point creeps above 200°C, which helps it hold its form during heating but eventually sends it off as vapor. It doesn't mix well with water but dissolves quickly in ethanol, ether, or other organic solvents. Its freezing point sits low, making it easy to store at room temperature without worry. The molecular structure—ethyl groups propping up a malic acid core—offers just the right level of reactivity without being unpredictable, so chemists can count on it to perform much the same way across different batches.

Anyone who’s ordered diethyl malate for research or industrial use knows thorough labeling always matters. Labels state purity, usually in the range of 98% or higher, and call out traces of ethanol or water leftover from synthesis. Bottles often come with hazard icons reflecting mild eye and skin irritation, so gloves and goggles aren't negotiable. Most suppliers provide the batch number, production date, and safety data sheet, laying out handling guidance and emergency information. Shelf life extends several years when stored cool and dark, minimizing contact with the air. Labs and production plants need this reliability to tick off checks for quality controls, ensuring that one batch lines up with the last.

Here's where base chemistry steps up. Most producers synthesize diethyl malate by starting with malic acid. By adding ethanol and just a touch of acid catalyst like sulfuric acid, the mix heats under reflux conditions. Water forms and gets removed, tilting the reaction in favor of ester formation. Once the reaction hits completion, the solution cools, gets neutralized, and water gets extracted, often using a separating funnel or rotary evaporator. The raw product still holds some impurities, so a round or two of distillation kicks out unreacted alcohol or side esters. This process keeps the integrity high so chemical reactions down the line go smoothly.

If you look to tweak diethyl malate, the two ester groups open several doors. Nucleophilic attack by an alcohol or base lets you switch or break these groups, changing the molecule’s properties or leading it towards entirely new products. Reduction can shift the molecule toward simpler alcohols, while hydrolysis—under the right acidic or basic conditions—releases the original malic acid. For synthetic chemists, this flexibility means diethyl malate doesn’t just sit on the shelf: it’s a real working tool, one that can morph according to the route you’re designing, whether making pharmaceuticals, polymers, or specialty monomers.

On chemical order sheets or catalogs, diethyl malate doesn’t always show up under the same badge. Some know it as malic acid diethyl ester. Others label it ethyl malate or diethyl 2-hydroxybutanedioate. In fragrance work, you might spot its code names or original trade monikers. International suppliers often use translations of its basic structure, so cross-referencing by CAS number (87-13-8) clears up confusion. It pays to watch for close cousins, as monoethyl or methyl analogues appear in similar contexts, though they perform differently in lab or industry.

People working with diethyl malate stick to basic lab safety: gloves, goggles, lab coats, and well-ventilated spaces. Splash risk into eyes or onto skin warrants a full drench in the safety shower or eye-wash station. The flash point keeps above most room temperatures, but open flames or hot plates intensify the risk of flammable vapors, so smart workers keep ignition sources away. Inhaling its vapor won’t tip you over right away but can irritate airways—so fume hoods stay in use during transfers. Material safety data sheets (MSDS) spell out procedures, and facilities store diethyl malate away from oxidizers or acids that could provoke unexpected reactions.

Though not a household staple, diethyl malate finds its purpose behind the scenes in diverse industries. Flavors and fragrances benefit from its subtle bite and pleasant odor, adding dimension to synthetic apple, peach, or grape profiles. In organic synthesis, it’s a trusted intermediate, lending its structure to textiles, surfactants, and specialty polymers. Pharmaceutical research taps diethyl malate to construct more complex molecules or as a substrate for exploring new reaction routes. Its solvent properties draw attention in coatings and ink formulations, providing a balance of solvency and evaporation rate. Electroplating, agriculture, and even analytical chemistry pull it out for niche purposes that only a malate ester can match.

Ongoing research looks past diethyl malate’s routine uses, exploring how its structure can lead to greener chemical routes. Scientists keep pushing for milder catalysts and lower energy processes, trimming waste and hazardous byproducts. Some groups are screening it for bio-based manufacturing, asking whether renewable feedstocks can yield the same quality at scale. Advances in catalysis, especially those using enzymes or solid supports, show promise in dropping production costs while improving product purity. Each improvement in synthesis or analytical technique often reopens old questions, leading to better understanding of how this ester fits new technologies or eco-friendly applications.

Safety studies downplay acute risk for most standard uses, but researchers haven’t stopped investigating long-term exposure. Animal models highlight relatively low oral toxicity, although high doses can disturb metabolism or liver function. Skin and eye contact bring irritation, driving companies to mandate protective gear. Regulatory agencies track changes in occupational exposure guidelines, flagging the need for better data on chronic inhalation, reproductive effects, or breakdown products after environmental release. Food and fragrance chemists pay close attention to allowable intake levels, seeking out more precise risk evaluations for consumer products. As science deepens understanding, industry best practices tend to get stricter in kind.

For diethyl malate, the next decade promises broader use in sustainable chemistry as companies push to redesign supply chains. Producers examine pathways to generate it from bio-waste or fermentation, hoping to cut petroleum out of the equation. Formulators in coatings, resins, and flavors invest in alternatives to harsh solvents or precursors with poor safety profiles, making diethyl malate a candidate for green replacements. As advanced manufacturing moves toward precision fermentation and closed-loop recycling, this unassuming ester could play a part as a versatile intermediate. Industry experts expect regulatory frameworks to catch up too, focusing on lifecycle assessments and environmental impact from cradle to grave.

Diethyl malate doesn’t show up in ordinary conversations, but it plays a big role behind the scenes. People in the chemical industry often count on it as a building block. It forms the backbone for things like flavors, fragrances, and pharmaceuticals. Manufacturers turn to it for its clean, fruity notes that can mimic apples or other light fruit flavors, all without breaking the bank or introducing risky additives. Products on store shelves—including candies, sodas, and perfumes—often owe their unique scents or tastes in part to diethyl malate.

Chemists value its mild, reliable properties. In the lab, it helps create more advanced molecules. Drug researchers and fragrance experts both use it to string together new chemicals, since the malate backbone fits nicely into all sorts of complex reactions. One reason it stays popular: it doesn’t cause a lot of irritation or bad reactions, so it keeps processes safe and predictable.

Agriculture finds some uses for diethyl malate, too. Researchers exploring crop protection or growth often look at diethyl malate as a middle piece in larger compounds. Certain pesticides and plant regulators might owe their success to this ingredient, even though no one talks about it directly. It’s a specialty item, but it can make a difference in everything from boosting fruit flavors in processed foods to strengthening certain plant treatments.

Safety checks and environmental controls stand front and center when people handle diethyl malate. Industry experts choose it because it usually has a better safety profile than harsher chemicals. My own experience in quality testing taught me that good supply tracking and monitoring can make a major difference. We kept tight logs in the lab and avoided unnecessary waste because one slip in chemical handling brings real risk to teams and communities. Transparency and oversight help keep things sustainable.

Pharmaceutical work sometimes taps diethyl malate, especially as an intermediate. It doesn’t end up as the medicine you swallow, but it helps create key ingredients. Some products for the heart or nervous system rely on a chain of chemical reactions that use diethyl malate partway through. There’s a certain pride in finding connections like this, where one quiet ingredient can launch a dozen helpful remedies.

Very few side effects come up with this ingredient, as long as people use it as intended. The FDA and European Chemical Agency both keep close tabs on anything touching the food or medicine chain, and so far, diethyl malate clears those bars. In my own work talking to flavor chemists, I’ve seen how important it is for companies to review each ingredient, even at tiny doses. Scrutiny keeps products honest, and helps people trust what they eat or put on their skin.

Researchers regularly look for safer, greener ways to shape basic chemicals. Diethyl malate stands out because chemists can make it from malic acid, which comes from natural sources like apples or grapes. Moving away from oil-based chemistry toward natural feedstocks can mean cleaner production with fewer toxic leftovers. More companies look to close the gap between synthetic convenience and environmental responsibility these days.

If more folks in the industry share research, support better production methods, and stay transparent with labeling, safer choices will reach the public faster. That’s something I’ve seen make a real difference—not just in chemical supply chains, but for families and communities who want to know what’s really inside the products they rely on.

Diethyl malate comes from malic acid, an organic compound found in apples and many other fruits. From a chemistry standpoint, it’s a colorless liquid known for its fruity smell and use as a flavor enhancer. Food companies sometimes use it in tiny amounts to add a tart note to beverages and candy.

I’ve learned the hard way that checking if something is genuinely safe means more than trusting it appeared in a few food lists. The biggest question is always whether studies have examined how a substance behaves inside the body, especially after frequent or long-term intake. For diethyl malate, safety data carries some gaps.

The U.S. Food and Drug Administration doesn’t list diethyl malate as a food additive with GRAS (Generally Recognized as Safe) status. Neither the European Food Safety Authority nor other global regulators give it a green light for deliberate use in foods. Even in scientific papers, researchers usually focus on its chemical properties, not what happens if humans digest it. One study from the Journal of Agricultural and Food Chemistry (2012) notes its occasional presence in trace amounts in ripe fruit, but that’s different from ingesting a spoonful or even the gram-level amounts you might see in supplements or industrial recipes.

Safety isn’t just about whether a compound causes immediate poisoning. Long-term effects deserve attention too. Anyone familiar with controversial additives knows that once a substance moves from trace natural sources to concentrated food ingredients, risk profiles can change. Diethyl malate’s toxicity profile remains incomplete. The National Library of Medicine’s PubChem entry notes potential skin and eye irritation based on animal testing. Inhalation or direct skin exposure isn't the same as eating, but it still raises eyebrows.

More troublesome are metabolites—what your liver does with foreign molecules. Malic acid itself breaks down easily and safely in the human body through regular metabolic routes. Its ethyl ester, diethyl malate, could theoretically do the same, but nobody has published thorough data on breakdown rates or possible byproducts in people. In the worst case, some esters break into alcohol-related compounds that the body processes less efficiently. Without animal feeding studies or clinical trials, it would be reckless to claim absolute safety.

Whenever I see a new name in ingredient lists, my first move involves a little research. Questions like: “Is it approved by recognized authorities? Have people eaten this for decades without harm?” For diethyl malate, big food safety agencies haven’t given clear answers. Its use remains rare compared to malic acid, citric acid, or other natural tarteners. Food allergies are rare, but sensitivity is possible whether from contaminants or the chemical itself.

Some companies look at structurally similar compounds as a shortcut. That approach works sometimes, but biology throws curveballs. Lessons from propylene glycol, sodium benzoate, and other molecules remind us that just because something sounds similar doesn’t guarantee the same safety margins.

Anyone thinking about products containing diethyl malate should check for reputable certifications and clear regulatory backing. If a supplement or packaged food boasts about “novel flavor esters,” asking for third-party testing data makes sense. Individuals with liver or kidney conditions may want to steer clear, since those organs work hardest at processing unfamiliar chemicals.

With so many food options available, sticking to well-researched, time-tested ingredients gives peace of mind. This isn’t about fear—it’s about informed choice and demanding strong evidence behind anything meant for regular consumption. I'll always read labels and trust my gut instinct, especially where safety data runs thin.

Diethyl Malate stands out as an organic compound that turns up in both industrial chemistry and biotechnology. Its chemical formula is C8H14O4. At first glance, this string of letters and numbers hardly offers much for most people, but real value shows up when you dig into what this formula means and why it matters in real-world use.

Seeing a formula like C8H14O4 on a materials data sheet or in a chemistry report always takes me back to my undergraduate days, spent huddled around a lab table, separate chemicals pouring into beakers, each creating a new possibility. Here, C8H14O4 spells out a molecule with 8 carbon atoms, 14 hydrogens, and 4 oxygens. These elements build a backbone that connects to diethyl ester groups on the malic acid skeleton. That’s no minor detail—diethyl malate hangs right in the balance between the flexibility of esters and the reactivity of malic acid itself.

Diethyl Malate isn’t something you find on grocery store shelves. Still, it quietly plays a part in multiple industries. It’s used as an intermediate in the synthesis of pharmaceuticals. Chemical manufacturers rely on it to tweak drug molecules just enough to improve their effectiveness or make large-scale production smoother. Some labs use it as a flavor additive for food experiments. In discussions with colleagues who've worked in quality control, I’ve learned that its purity and consistency can make the difference in how reliably test results turn out, especially during critical synthesis steps.

Anyone who's handled organic solvents and esters in a chemistry lab knows these chemicals need careful attention. Even though diethyl malate doesn’t have the drama of the more volatile esters, it still requires basic safety—gloves, goggles, and proper ventilation. There’s nothing glamorous about a splash in the eye or a spill on the skin. Long-term exposure can bring risks, and responsible professionals minimize hazards by sticking closely to safety data sheets. In the chemical industry, mistakes from skipping safety rules can cost both time and health. I’ve learned the hard way that even a short lapse in judgment during cleanup or transfer can turn routine work into a serious problem.

Production often raises problems with yield, byproducts, and cost efficiency. Getting the chemical synthesis route right for diethyl malate means balancing raw material choices, reaction temperatures, and waste treatment. I’ve seen small-scale setups get clogged with byproducts because the reaction control scripts missed a variable or two. Manufacturers can deal with these issues by integrating feedback systems in their reactors, investing in better purification columns, and training operators to spot trouble signs early. On a larger scale, responsible sourcing of raw materials and disposal of waste esters cuts environmental impact.

Understanding a chemical’s structure isn’t just for academics or lab geeks. Each formula tells a story about functionality and safety. Knowing that diethyl malate measures up as C8H14O4 opens up opportunities in process optimization, safe handling, and product development. For the folks in labs and factories shaping these molecules into real-world products, clarity about what they’re using makes all the difference.

Storing chemicals in a safe and thoughtful way has always sparked more conversation than it gets credit for. Diethyl Malate is one of those chemicals that flies under the radar for most folks, usually found in flavors, fragrances, and sometimes in the lab. Fact is, how you keep it tucked away matters more than most realize—both for personal health and the well-being of anyone nearby. Taking shortcuts can lead to dangerous slip-ups, and I’ve seen enough close calls in busy workspaces to know it’s worth talking about.

Safety data sheets for Diethyl Malate always point out the same basic hazards: the liquid can irritate if it spills or splashes, vapors may not smell as bad as some chemicals but still pose risks, and improper storage raises the risk of fire. A simple error like stacking bottles too close to a heater or sunlight can boost those chances of combustion. In my early days running a modest research lab, I watched a seasoned coworker rush to stash bottles out of sight, forgetting that hot water pipes ran nearby. A week of slow heating caused a container to bulge and, fortunately, pop its cap in an empty room. Bad luck could have led to a fire or harmful exposure.

A cool, well-ventilated cupboard away from direct sunlight works best for Diethyl Malate. Don’t just glance at the room temperature display. Heat tends to build up in small points—near windows, up high on shelves, or right next to electric panels. I like using a standalone cabinet set aside with lockable doors, especially one lined with chemical-resistant shelves. This isn’t overspending; it’s peace of mind. Only trained staff should get the keys. A chemical like this doesn’t belong in a communal storeroom or somewhere janitorial supplies might get mixed in by mistake.

Ventilation seems boring until fumes gather. I once saw a shared storeroom lose fresh air during a power outage—chemical odors crept through the building by morning. Good air flow, backup fans, and well-marked exits kept us clear, but the scare stuck. Storing diethyl malate around fresh air—never a sealed closet—should always sit at the top of any storage checklist.

Manufacturers use tightly sealed glass or high-density plastic containers for good reason. Glass doesn’t react, and tough plastic won’t crack from a small knock. Always check containers for stress lines and crust around lids. I make it a personal habit to write the opening date and initial on labels, especially if there’s a team using the same supplies. Sharpie scribbles might not look fancy, but they help spot out-of-date stock and track possible leaks. Mixing up bottles leads to all sorts of trouble—labeling is a basic step that keeps work and workers safe.

Stuff goes wrong. Spills can and do happen, even with steady hands. I learned the hard way: Speed and preparation save the day, not panic. Spill control kits (with absorbent materials and gloves), eyewash stations close by, and fire extinguishers rated for chemical use all belong in the same room. Set a plan, walk through it with the team, and don’t store anything until everyone knows what’s on hand for emergencies. Knowing how to act quickly has kept people safe and workspaces calm.

The chemical industry keeps looking for compounds that can deliver consistent, recognizable sensory experiences. Diethyl malate steps into this scene as a popular additive for both flavors and fragrances. Fruit flavors often rely on esters, and diethyl malate can help build the smooth, rounded notes found in peach, apple, and grape flavors. In perfumery, it helps create a subtle, green freshness that perfumers use for nuances in their blends. Many mass-market beverages and candies rely on this ester for a fruit-forward aroma because lab synthesis can keep up with global demand.

Cosmetics manufacturers want ingredients that are safe, stable, and gentle on the skin. Diethyl malate gets used in lotions, deodorants, and aftershaves, not just as a filler, but because it can improve the texture of products. Chemists value compounds like this for delivering a light, velvet-like finish in creams or balms. The ester structure also helps reduce the greasy feeling many heavy emollients cause, so it can boost product appeal among shoppers wary of oily skin. Its safety profile—supported by data from regulatory agencies—matters to any parent choosing skin products for kids or people with sensitive skin.

Many pharmaceutical processes rely on small, stable molecules to help build complex medicines. Diethyl malate serves as a building block in the preparation of various drugs, especially where a malate moiety is needed in the synthesis. It offers a way for chemists to introduce the right functional groups into a target molecule. Large-scale manufacturers value this efficiency, since it can cut down both time and cost. A reliable intermediate like this keeps supply chains stable for companies making treatments for heart disease or certain metabolic disorders.

Growing crops at scale calls for pesticides and herbicides that are both effective and manageable in terms of safety. Diethyl malate finds a place as a starting material for certain agrochemicals, where its reactivity lets engineers develop products that break down in the soil or degrade with exposure to sunlight. The balance between efficiency and biodegradability has become a bigger concern, and additions like these offer one small piece of a larger effort to reduce environmental impacts without giving up reliability in crop production.

With growing pressure on companies to deliver safer, more sustainable products, chemicals like diethyl malate face scrutiny over sourcing and environmental impact. Reliable scientific studies suggest this ester operates with a relatively low toxicity profile, which helps maintain regulatory approval across the US and EU. Still, quality assurance teams want tighter controls on impurities and sourcing, since subtle chemical differences might affect outcomes in medicine, food, and fragrance.

Sustainable production draws new focus. Producers look at bio-based routes, cutting down fossil-fuel reliance. Companies willing to invest in greener chemistry have a chance to keep diethyl malate viable across its key markets.

| Names | |

| Preferred IUPAC name | Diethyl 2-hydroxybutanedioate |

| Other names |

Diethyl malonate Malonic acid diethyl ester |

| Pronunciation | /daɪˈɛθ.ɪl ˈmæ.leɪt/ |

| Identifiers | |

| CAS Number | 87-91-8 |

| Beilstein Reference | Beilstein 1721392 |

| ChEBI | CHEBI:4429 |

| ChEMBL | CHEMBL49091 |

| ChemSpider | 59402 |

| DrugBank | DB14096 |

| ECHA InfoCard | 03bfa8ec-02f7-4b4a-8a64-e7906ee7e4ce |

| EC Number | Diethyl Malate: 623-76-7 |

| Gmelin Reference | 6137 |

| KEGG | C06035 |

| MeSH | Diethyl Malate |

| PubChem CID | 11453 |

| RTECS number | OI9100000 |

| UNII | 36F5UJ2A6C |

| UN number | UN2529 |

| Properties | |

| Chemical formula | C7H12O5 |

| Molar mass | 174.19 g/mol |

| Appearance | Colorless to light yellow transparent liquid |

| Odor | Fruity |

| Density | 1.082 g/mL at 25 °C(lit.) |

| Solubility in water | Slightly soluble |

| log P | -0.26 |

| Vapor pressure | 0.02 mmHg (25°C) |

| Acidity (pKa) | 5.62 |

| Basicity (pKb) | pKb: 15.74 |

| Magnetic susceptibility (χ) | -61.5·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.418 |

| Viscosity | Viscous liquid |

| Dipole moment | 2.51 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 309.5 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -1,061.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | –2226.6 kJ·mol⁻¹ |

| Pharmacology | |

| ATC code | A15BA02 |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes serious eye irritation. Causes skin irritation. |

| GHS labelling | GHS07, GHS08 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H315, H319 |

| Precautionary statements | P264, P280, P305+P351+P338, P337+P313 |

| Flash point | 111°C |

| Autoignition temperature | 225 °C |

| Lethal dose or concentration | LD50 (oral, rat): 7400 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50 = 3200 mg/kg |

| NIOSH | FGD |

| PEL (Permissible) | PEL for Diethyl Malate: Not established |

| REL (Recommended) | 30 mg/L |

| IDLH (Immediate danger) | 800 ppm |

| Related compounds | |

| Related compounds |

Diethyl succinate Diethyl fumarate Diethyl maleate Diethyl tartrate Dimethyl malate Ethyl malate |